https://www.printables.com/model/759734-oreck-vacuum-tube-extension#preview

Replacement tubes are only about $15 but why spend that when I can just print them!

No, this is a vacuum tube: https://en.wikipedia.org/wiki/Vacuum_tube

That was my first thought as well. I was going to be incredibly impressed if OP managed to 3D print a vacuum tube.

That or get a laugh at a 3D printed dummy vacuum tube in a $1K audiophile amp.

I read that in an Australian accent.

Though point of technically. It’s a tube. And it attaches to a vacuum.

But he did not call it “a tube that attaches to a vacuum.”

too many words, and I’m not cool enough to just call it a “tubeythingthatattchestoavacuum.”

So, Vacuum Tube makes sense.

No, this is a vacuum tube: https://en.wikipedia.org/wiki/Vacuum_tube

See, and I went with Patrick. Oh pop culture. Unless, of course, you are Australian. Then, my warmest regards!

My accent is Californian by way of Minnesota.

Yes, I get weird looks when I ask for a sodah instead of pop.

Man, I’m old. I was wondering how in the heck you 3D printed a glass and metal vacuum tube.

Sintered glass and using solder like filament!

(Okay that might be too ugly, even by my standards….)

No current hobbyist sintered glass printer can make a vacuum vessel that can withstand the needed negative pressure unless you make the walls prohibitively thick and even then probably not.

edit: Downvoted for objective fact, now you’re blocked asshole

That’s funny. FYI… I’m not the one who downvoted you.

Second fyi… you can post process. For sintered glass, you can print the part and then fire it either in a kiln, a furnace or an a torch.

Finally, you speak with such authority on what mere hobbyists can do. I wouldn’t put any wagers on that.

LOL yeah, not sure what else to call these, its a tube and its for a vacuum.

I honestly think this is the worst use case for a 3d printer. The part isn’t improved by printing. You can buy the part easily. The cost of modelling time and printing is more than the replacement. There’s a decent chance the replacement part would have arrived quicker than the print took… Sorry to be a bore, it’s better than an octopus or another benchy, I’ll give you that.

Modelling took less than 2-3 hours, and print was overnight so unless Amazon has drone shipments to my area this was faster. Cost in Filament was around $6. All told I think I ended up on the plus side with faster “service” and lower cost.

You also got CAD experience from this so the next one will be faster too.

The cost of modelling time

my brother in cad, it’s a cylinder. a tube.

Well you’ve clearly never 3d modelled anything. Especially for a part that has to fit to existing parts, it takes far more time than just making a cylinder.

lololol

I started with 3dsr3 on dos bro. I design and model my own prints, ranging from input devices for vr to cosplay bits for the kiddos.

Yeah, I mean you’re gonna have to bust out the calipers… I don’t mean to suggest there are one-step shortcuts, but at the end of the day, you have an exterior diameter and interior diameter to worry about so it fits other bits, and external details that may or may not be needed (flutes to strengthen the design for example). But for all that you’ll spend way more time dialing in and printing tests to find the best orientation and support / adhesion / extrusion / infill etc…

but the modeling itself? an hour, a test print, fit test, adjustments, another test print (tests don’t need to be all of the model btw, if you’re just testing for fit to other parts!), then you should be on your way to a usable prototype. the cost of modelling should be the smallest sink in time cost.

Excuse my ignorance, I don’t know much about 3D printer material types / filament resistance, but from a few 3D printed cases for small devices I had, isn’t the plastic brittle? Or the joints of layers. Especially for a long cylinder shape where force is going to be applied to. I dropped 2 cases on the floor and they broke in multiple pieces where 2 layers of filament joined. But granted, their thickness was 2-3 millimeters.

Phone cases should probably be printed in TPU, which really shouldn’t be shattering. (Unless it’s freaking cold outside.

Maximum drop protection. Would come from a hard shell over a squashy TPU case.

There’s really not that much force on these kinds of things, of greater concern is air flow but it looks like op nailed that.

(If op had taken it down to a smaller diameter, cut outs in the nozzle or somewhere would be be necessary- otherwise the vacuum’s motor has to work too hard to get proper air… and they rely on that flow to cool down.)

Yes normally the tube gets inserted into another tube, which is the stuck into another tube or a foot. This leaves a large moment force directly where the tube is pushed into the other tube. Most likely even with careful use, this tube will break very quickly. The layer joint is the weak spot and the type of plastic most likely isn’t ideal.

Vacuum cleaner parts are made from a high impact plastic, something that’s tough but a bit on the softer side. This way it can take a beating without breaking into a million pieces.

3D printing this is cool and impressive to pull off such a high and narrow print. But practically speaking it makes no sense.

It depends on material type, print settings and design itself. While injection molded parts are usually stronger, 3D printed parts can survive a lot of stress if built correctly (some printers are built from 3D printed parts for example). But you are right, OPs tubes might not survive for too long (it will break between layers most likely). I wish it survives for many years tho

On the other hand, 3D printing is not only used to build better and cheaper parts, its a hobby for lot of us. The ability to imagine, create a 3D model and build the part at home makes me feel powerfull. Its almost always better (cheaper, stronger, faster) to use other technologies or just buy something, but where is the fun 😄

You are correct that injection molded plastic is generally stronger than FDM. I have a well tuned printer, and I use a .6mm nozzle which gives better layer adhesion than the standard .4mm while not having to sacrifice too much detail. I also print in a tent to keep the air warm and gain some effect from annealing the plastic which makes prints slightly stronger.

I mean sure, but if someone does it as a hobby then there is the fun and accomplishment value out of it too

Very brave not to use brims on those

Why buy a $15 replacement when I can print one from $20 of filament?!

(I kid)

@JakenVeina Printed in diamond infused PLA? 😂 Rarely a single print take one full spool of filament

Was expecting actual vacuum tubes, not a fucking vacuum wand.

Blocked.

Did you make them better than the original, solving problems that have bugged you since you bought it?

not specifically, but because of the limitations of my printer its actually more more module so you can use a single one hand held easier.

That is some seriously beautiful print quality. Mind sharing what settings you use?

- 0.6mm Cooper clad Nozzle

- 0.3 Layer height

- 1.2 wall thickness

- 4.0 retraction

- Use Adaptive Layers on

Filiment is Polymaker Pollyterra Charcoal Black

- 190c/50c

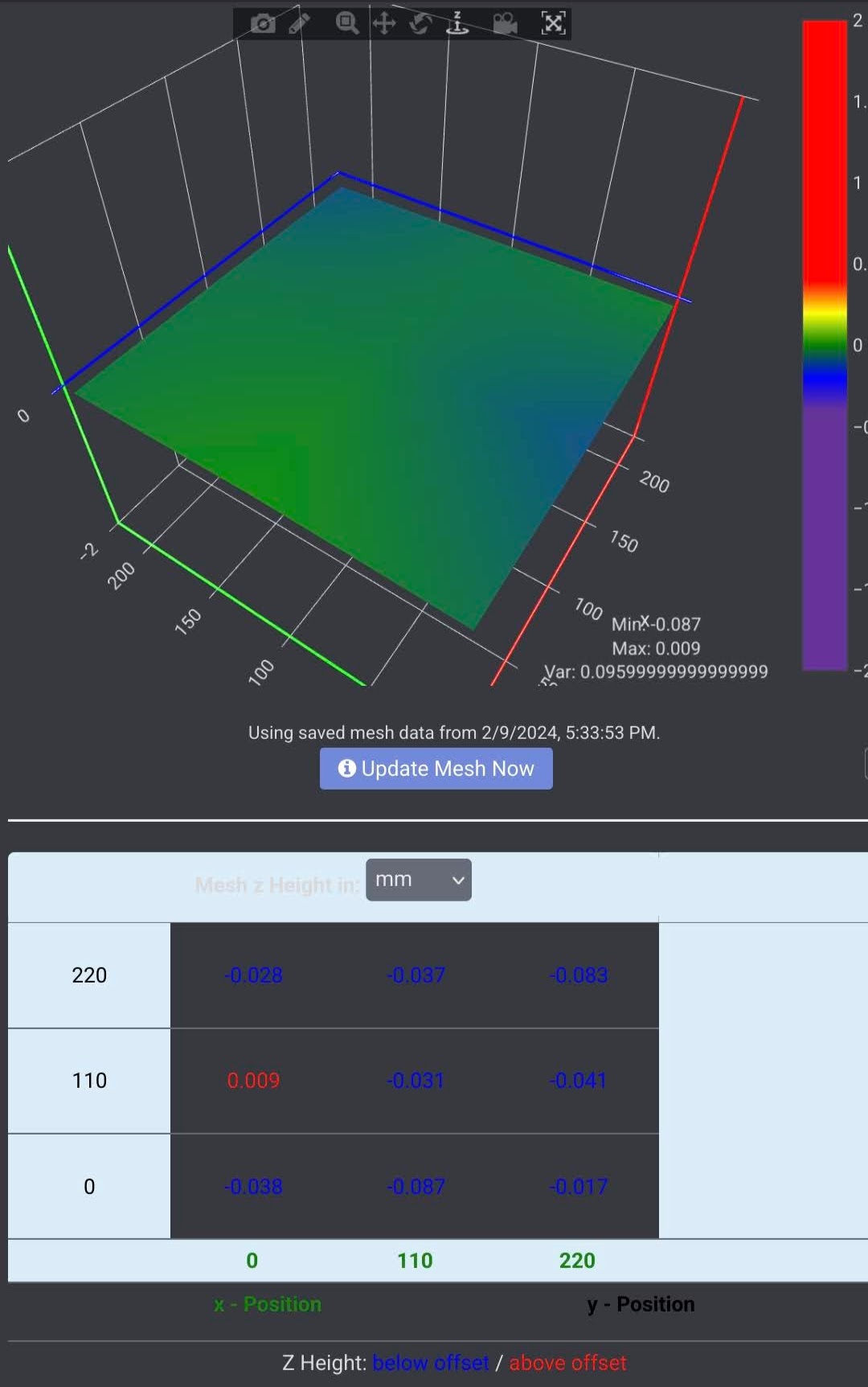

The rest comes down to tuning, print settings only account for a small part of the quality in my experience. So I put lots of time into making sure my esteps are spot on, my bed is level, I have trammed all the corners.

deleted by creator

New Lemmy Post: Partner broke the vacuum tube, so designed and printed replacements. (https://lemmy.world/post/12057257)

Tagging: #3dprinting(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md