phillips worst screw self stripping garbage

That is actually a feature of this design. They were the answer to in-line screwdrivers who had no precise stopping torque: cam-out before the thread is damaged.

I know it’s an intentional feature, but it’s a bad feature. Camming out damages the head of the screw. This exchanges repairability for manufacturing simplicity. Additionally, the sloped shape makes it possible to use slightly oversized or undersized drivers, further increasing the chance of camming out and damaging the screwhead.

To your point it’s a compromised solution for a problem that no longer exists.

Bug turned into a feature: https://handwiki.org/wiki/Engineering:Cam_out

Torx is the only head that needs to exist. The rest can go fuck a rusty chainsaw.

Square is really good too.

Phillips and flat head bits fit in a variety of sizes of screw heads. We seem to have chosen convenience over performance.

If memory serves me correctly square drive is patented, & thus requires licensing, which is why it’s less commonly used.

deleted by creator

And then bolts

This is the way. Also I’m new to Lemmy so forever will this be how I start my experience here.

Torx is hands down better in every way than flathead and Phillips.

Slotted heads, Philips, posidrive, torx, 6 pan and Robertson.

Each has a use, for instance a slotted head, when you don’t need much torque is good enough (like for a screwed in battery compartment).

The torx are the most resistant, the rest can also cease to exist.

Anyone who willfully uses a slotted screw on a new project in the presence of even somewhat reasonable alternatives should have a lifetime ban on designing any items for anyone.

Also, use Robertsons, gink.

it’s single valid use: somewhere that you may not have tools but might require an impromptu fix… preferably paired with a much larger screw than technically required so you can use things like coins as a driver

Yeah, like mounting plates for cameras…. Um, I think that’s the only place I’ve appreciated a slot screw

Sewing machine too! Always using scissors to open that slot screw to change the needle

We put slots on the thumbscrews used on some of our connectors for military radios. This was a soldier can open or tighten them down with a knife blade.

No.

Thumbscrews, or wingnuts.

Fuck electrical wall plates I guess then? It’s so hard to find any switch plates or device plates that come with Phillips instead of Slotted.

Yeah fuck them, i hate those stupid slippery slotted bastards

Torx is great but fuck security torx

security torx

Do you know what’s the deal with them except having to pay / find extra bits?

They’re designed so the average person isn’t gonna have the tools to mess with them.

Most of the sets I own have a hole in them, so I think for the scenario that the average person does actually have a torx set, the chance is pretty high that it’s also one that they can use on those “security” torx screws. So I don’t see them that much more secure than regular torx. The only reason I could think of is that you also can use a normal screwdriver to unscrew a torx, which is harder to do with that extra pin. But it can still be done^^

It used to be more secure but manufacturers started to just put a hole in all of their torx bits to compensate lol. Now it’s pretty much pointless

If you’re determined enough you can jam a slot screwdriver in a torx and turn it, the security bit makes it so that you have to be REALLY determined when you jam the slot screwdriver in

You could drill your torx but (not advised) or drill the pin(?) on the screw.

My favorite is hex, self centering and doesn’t strip easily

Hexagons are the bestagons

Only in 2D. Screws are 3D. There is no known optimum in 3D.

Torx are the better hex as they apply torque to six planes, not six lines. It’s right-out impossible to strip a torx.

The disadvantage is that it’s harder to machine but that really doesn’t matter for cast screws. Tools are also cheaper that’s why IKEA etc. use them.

Unless they are in a facemill or something for a milling machine

Torx tools are cheaper? I didn’t know that. I’ve never really come across them, so I didn’t think they were an option for universal replacement.

Nah, cheap hex tools are cheap, those one time use allen wrenches. Torx comes with a higher minimum quality as you can’t just bend some rolled hex stock and have something that passes as a tool.

High-grade bits are expensive in either case, shape doesn’t matter much in that segment so tradespeople go by what’s the best shape and that’s torx. Really makes a difference when you’re going through thousands of say drywall screws a day: They never cam out, you can set precise torque with an actual torque limiter and screw them in at ridiculously high speeds without pressing down on the screw. Aim, fire, done, next, especially if your whatsitcalled in English has a magazine.

(if you over-torque a torx screw one of two things is going to happen: Either the screw head breaks off, or the bit. Also a kind of torque limiter)

In other applications they might be overkill but only having one type of screw around makes up for the minimal amount that torx is more expensive.

Things like external hex or if you want squares or really whatever of course also have their place, no matter the even number of sides it’s all wrench flats.

And for some reason electricians are fond of their combined flat/pozi screws. First outlet manufacturers used flatheads, then when switching to pozi they realised that while J. Random Consumer might have pozi screwdrivers their one insulated one is a flathead so they combined the shapes, then along come electricians and buy screwdrivers for that combined shape because it self-centres and nearly self-rotates and doesn’t cam out easily.

Canadian here. I’m offended the Robertson (square) has been shamed like this.

Robertson head gang represent. It’s just so good.

💯

Best deck screw of ‘em all.

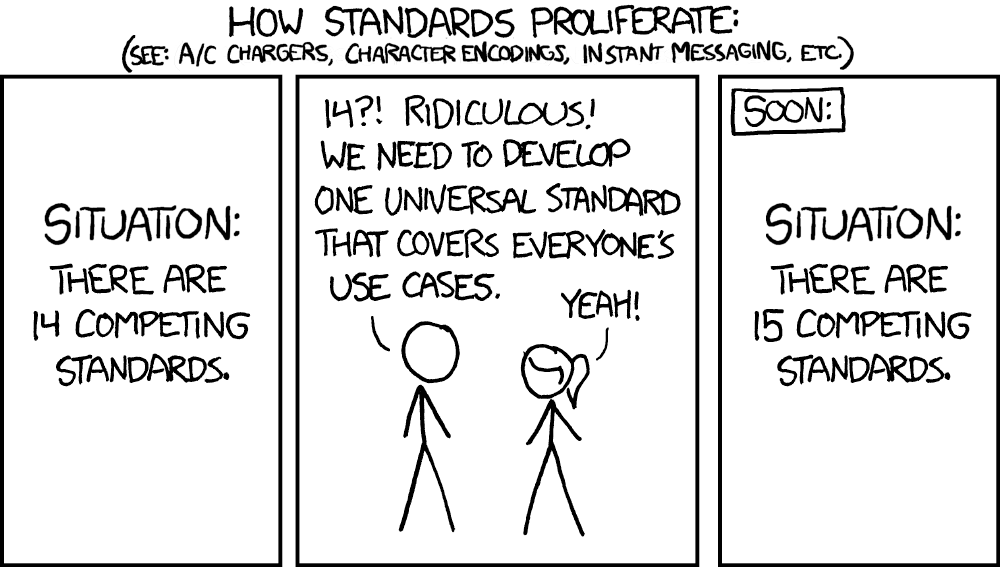

Situation: There are 20 screw standards.

John Corporate: “20 standards… I know, I’ll create a new type of screw that will be unique to my corporate overlords and prevent users from repairing their own devices!”

Situation: There are 21 screw standards.

Relevant xkcd:

To be fair, UTF-8 did win the character encoding wars. Kudos to the Unicode designers I guess.

USB also won the cable data war. The 2000s era cables is wild

Yeah, given enough time sometimes one of the standards will win and kill the others, it kinda just depends (in part on luck)

Wish Windows knew that

Square is called a Robertson and is the standard for construction in Canada. None of that bullshit Phillips trash.

Not only the standard screw but a very effective head shape. The head is both self centring and can hold on the screw securely and without the use of magnets.

I will die defending Robertson screw as a top contender. The rest of the world must learn our superior Canadian ways, by force if necessary.

It’s 100% superior to anything else I’ve used. If you use a good quality screw driver or bit, they’ll NEVER strip, even using an impact driver.

The real “actual screw”.

Canada is a very progressive place it seems

Robertson or gtfo

Lately I’ve seen a lot more Phillips Square, which is nice when you strip the fuck out of the Phillips head. Those are alright.

Pozidrive is basically a Robertson and Phillips on top of each other.

I hate phillips. It seems like their only purpose for existing is to strip out so that you can never remove them.

Personally, any time I have a project, I always opt for torx (star). The screwdriver bits for them are not tapered so they don’t push themselves back out of the screw-head (unlike phillips), so they tend to stay in place and grip much better. It’s a lot harder to screw up a torx screw or bit than a phillips one.

I. Love. Torx! They just work! Don’t mind the angle, don’t mind the force! They’re just perfect! Never going back. (At least for everything related to woodworking)

They actually were designed to cam out in low torque applications so consumers could not over-tighten them. The problem is now those consumers only know what a phillips is, so they’re used for everything.

Hilariously, that “purposeful cam-out” was the manufacturers/patent-holders trying to turn a bug into a feature. https://handwiki.org/wiki/Engineering:Cam_out

Same. I use torx for everything. Also gotta love the square Robertson ones, they’re just not common where I live. I hate Philips, although for anyone not aware, there is a difference between posi drive an Philips and going to the effort of making sure you have the correct one massively reduces torquing out and damage to screw head.

IMO, phillips is for electronics and some small applications. Something you’re really not putting much pressure on and probably driving by hand and not a power tool.

I strongly dislike how many times I’ve stripped a Phillips and used a die grinder to force it to become a flat. Torx is fine.

I used to restore “barn bikes”, most of them were Japanese. It took me a while to figure out the difference between Japanese Industrial Standard (JIS) and Phillips screws. Of course over the years, a lot of the fasteners had already been cammed out by previous owners using a Phillips screwdriver in a JIS screw. I had to resort to the die grinder method far more than I’d have preferred.

Torx or Robertson, are the only ones worth a damn.

I’m a Philips type of guy myself.

You have chosen…poorly

Hex screws are sick tho. Great when there isnt much space to tighten regular screws.

I like pluses and squares. Minuses need to be removed from existence

Minus is great because you can use a butter knife on a pinch to unscrew/screw it

Pozidrive is both!

Robertson, hex and torx should be on that list, the rest of that shit can stay in the scrap bin of designs